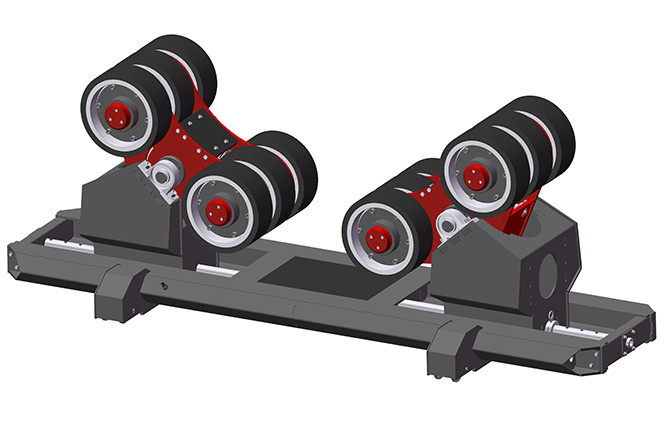

Roller positioner RWD 420

MACHINE VARIANTS

Necesary choice

The green color indicates an element or the part that have to be installed to the machine in one of the offered variants already during its production and the machine cannot be forward into the operation without it, or order it.

Construction surcharge

Yellow coloring means an element or the part which have to be installed into the machine in some of the offered variants already during its production. In principle it is a device extending functionality.

Free equipment

The gray coloration indicates an element or the part which is possible to fit the machine at any time later. Assembly is possible by the end user. In principle it is an equipment which expands functionality.

The purpose of the machine is to work in industry and in 7/24 mode. The sophisticated design of the positioner brings significant advantages and perfect variability for work in welding and handling of containers and round products. High-quality synchronized drives guarantee excellent dynamic properties of the unit in conjunction with the NEXT unit but also in cooperation with another CLEVER unit.

-

RWD 420 CLEVER is a self-adjustable roller positioner - working unit with the possibility of adjusting the roller gauge. The concept is a sophisticated device of high design standard, using only first-class components.

-

The steel frame structure supports tilting laterally movable support units with integrated drives by stepper motors for digital controlling possibility. In addition, stepper motors bring maximum rotation accuracy.

-

The support units are compact in design and their lateral position is fixed by a simple pinning system. If the positioner is operated on a track, the machine can be equipped with an ingenious pneumatic positioner lifting system, which allows the positioner to roll comfortably on the track.

-

The support units can be fitted with rollers with vulcanized rubber surface or CrNi steel surface. The design variation allows the choice of four, eight or twelve rollers. This makes it possible to achieve a minimum specific pressure on the vessel surface and thus eliminate the risk of deformation of the vessel shell. The system of transverse gauge adjustment together with the automatic tilting of the support units guarantees a perfect centric distribution of the pressure forces induced by the weight of the vessel.

-

The positioner is controlled by a digital remote control "Mighty Controller" with full display of all values. An electronic brake is fitted as standard to prevent the positioners from spinning under eccentric load. The machine can be equipped with a switching contact for controlling an external device, e.g. a welding machine. The unit can be connected to other CLEVER units (up to three units), thus multiplying the load capacity while maintaining perfect drive accuracy during welding.

-

The CLEVER version can also be integrated into other HST CREATIVE systems with digital controling.

Main benefits

√ Two step synchronized motors and gearbox of highest quality provide great dynamics and efficiency of the drive.

√ Minimalization of specific pressure on the surface of the cylinder quaranteed by self – adjustable carring units

√ Precise eccentric division of pressure powers caused by weigh of the cylinder thanks to adjustable wheelbase of carring units

√ Resistant industry design without risks of demage which could be caused by manipulation with burdens.

√ Fully - digital controlling which enables displaying of working parameters on „Mighty Controller“, possibility of controlling another CLEVER devices.

|

WORKING PARAMETERS |

VALUE |

|

Maximal static load - output of drives not mentioned |

15000,0 Kgs |

|

Torque on shaft of rollers |

2 x 1800,0 Nm |

|

Progress speed |

0,50 - 249,3 cm/min |

|

Duty cycle ** |

24/7 |

| DIMENSIONS |

VALUE |

| Minimal diameter of tank (all rollers touch the tank) | 900,0 mm |

| Minimal diameter of tank (only inner rollers touch the tank) | 200,0 mm |

| Maximal diameter of tank | 6000,0 mm |

| Diameter of rollers | 420,0 mm |

| Width of rollers | 140,0 mm |

| Number of rollers * | 4, or 8, or 12 |

| Standard distance between pulleys (on request possible to adjust)* | 1800,0 mm |

| Stroke of positioner from braking segments for easy moving along the pulleys * | 15,0 mm |

| MOTORIC AXISES | VALUE |

| Rotation of roller positioners | Controlled axis |

| Elevation of roller units (T axis) | Self - adjustable axis (gravitational) |

| Distance between roller positioners in pivots of T axis | - |

| Movement along pulleys * | Manual axis |

| TECHNOLOGY OF WELDING | VALUE |

| Suitable methods of welding | SAW, MIG/MAG, TIG, Plasma Weld |

| Connection of welding device through START/STOP system * | Yes |

| Remote control * | Yes |

| POWER SUPPLY | VALUE |

| Power supply | 3x400V 50/60 Hz |

| Pressure air (dry, clean) * | 0,5 - 0,9MPa |

| Description of working position * | Moveable along the pulleys |

| Levl of IP | IP 51 C |

| Input power for installation *** | - |

| DIMENSIONS | VALUE |

| Height | - |

| Width | - |

| Depth | - |

| Net weight *** | 2300 Kgs |

* Optional item, or more versions are available which differs according to function. Mentioned parameters are valid for maximal options.

** 8/5 = lower loading in one duty period /// 16/6 = industrial loading /// 24/7 = non - stop loading

*** Parameters can not be provided with 100% correctness. Configuration of the machine must be taken into consideration. Mentioned parameters are valid for reaching maximal effective value.

...Subject to change the technical parameters without notice.

Basic configuration of the machine

Basic equipment for automatization