Technical references

In this section possibilities of HST CREATIVE machines are briefly described (including technical know - how, level and class of controlled process of welding during mechanization and automatization).

Standard technologies supported by HST CREATIVE

- Rotary welding performed on the plate with elevation

- Rotary and longitudinal welding with clamping in the centre axis, inner and outer elevation (possible without elevation)

- Rotary and longitudinal welding on rotating rollers, inner, outer

- Screw and layer welding without elevation and screw and layer welding with elevation

- Longitudinal welding with both side fix clamping

- Plasma cutting of bevels in 2,5D

- Plasma cutting of plate materials in 2D

- Complex multitasking systems for fully automated process of welding

Welding methods for which are HST CREATIVE devices optimazed

- MIG short circuit (method of type 131*)

- MAG short circuit, open circuit, impulse arc (methods of type 135, 136, 138*)

- SAW (method of type 121, 123*)

- TIG DC continous arc, pulse arc (methods of type 141, 142, 143, 145, 147 *)

- TIG AC continous arc, pulse arc (methods of type 141, 142, 143 *)

- Plasma Welding continous arc, pulse arc (method of type 15 *)

- Plasma Welding Key Hole continous arc (method of type 15 *)

- Laser

* Welding methods according to ISO 4063

Concept and design of HST CREATIVE machines

- Rotary desk positioner with elevation

- Horizontal lathe welding automat

- Horizontal rotary lathe automat with elevation of the tailstock and control of torch position

- Universal rotary automat with elevation of the arm

- Universal rotary automat with elevation of the arm and control of torch position

- Roller rotary positioner with self - adjustable function and adjustable wheelbase

- Portal movable automat of GANTRY type with controlled position of the torch

- Roller rotary self - adjustable positioner

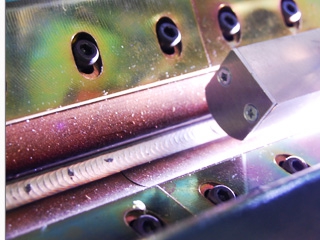

- Automat for longitudinal method of welding with precise clamping to copper underlay

Possibilities of control systems in the connection of production process

- Numerically controlled axises: R-rotary, X-longitudinal, Z-height, T-tilting, E 1, 2, 3 - another types of controlled axises

- Saving and naming of programs

- Program compilations - creation of whole production processes

- Touch control by LCD system

- Remote controls which can be programmed by the end user according to actual needs

- Possibility of program over - changing, system of UP/DOWN logic

- Digital camera enabling to check the whole system of welding including direct view into the weld

- CanBus communication between HST CREATIVE automats and welding machine (available from 06/2016)

- Control systems of the weld: Tactil, AVC (available from 09/2016)