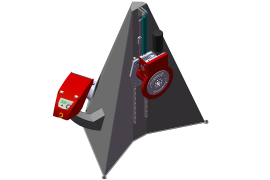

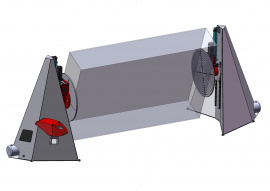

Rotary welding Positioner RWP 1350 LIFT

MACHINE VARIANTS

This machine is designed for hard work in industry use. The machine is characterized by a strong construction and perfect design of all components. High-quality drive guarantees perfect smoothness and constant rotate speed even under eccentric loads. The spindle can be lifted. The R3 control system provides basic functions for successful automation of the welding process. The machine also has a controlled output for switching of the welding source.

This is a special solution which is provided only as custom made. The final technical solution and possible feasibility of the project is provided as special project solution and always exactly based to the parameters of the required products, specific applications or the customer production program.

-

RWP 1350 LIFT is a heavy positioner with maximum working load of 2000 kg. It goes about a flawlessly and high-developed system of the highest construction level getting the possibilities of desk positioners above their conceptual possibilities. The spindle speed range is set lower, higher torque is available.

-

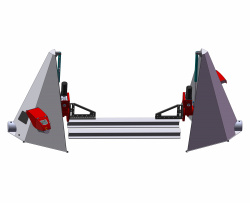

Stand steel construction include rotator, driving mechanism and huge spindle. The spindle has a flange giving the possibility of fixing the standard basic plate of 1350mm with grooves or universal chuck of 315mm. Control system R3 is integrated into the machine chassis and protected by the stell door with the polycarbonate glass cover against the suppression of the welded metal.

-

The lift of the rotator has hydraulic drive controlled by electric motor using buttons. The position of lift can be changed even when the welded product is loaded. With regard to the purpose of the machine the stroke length is 630 mm.

-

The work can be easier while using the foot speed rotation proportional controller which allows to set the speed of spindle rotation. Hand controller is another alternative for the remote control of the machine. In addition to controlling the speed of rotation both, the foot control and hand controller, may include a selector for the direction of rotation.

-

There is the possibility to deliver the machine with integrated system for setting the forming gas through the spindle.

-

The device is perfect and suitable for MIG/MAG and TIG welding methods including pulse arc and plasma welding.

Using possibilities in a terms of weld type and technology

√ Manual circumferential welding, remote control of the rotation speed, the possibility of switching the direction of rotation with an ergonomically integrated selector.

√ Connection of the welding source with communication cable directly to the positioner.

√ Lift of spindle continuously by hydraulic unit and electric motor by means of buttons.

X The spindle has a through hole for supplying the forming gas under the weld.

X The spindle has a through hole for welding of pipes.

X Linear and radial oscilation.

Main benefits

√ Digital stepper motor control provides stable rotational speed also with eccentric loading.

√ The control system supports welding automation. Setting the rotation angle and the welding source switch OFF angle.

√ Welding in manual mode with rotation speed control by proportional foot controller.

√ The machine can be connected into automated production system with welding source.

√ Durable design with protection of sensitive parts, transmission of welding current by a professional milled CuCrZr wiper.

The information given here describes entire R3 control system with all possibilities which however may not be available for every positioner depending on technological possibilities of specific positioner. It also depends on selected positioner configuration. Therefore is always necessary get acquainted with the specific positioner at first whether its technological possibilities, even with regard to the configuration you have chosen, support all functions described below, or not. Information given in here are the overview about possibilities ofcontrol system, not the positioner and do not give explanation of individual components because of difficult comprehensibility of more complicated functions and equipment. For more details, please, contact the technical department or sales of HST CREATIVE.

R3 Control system for rotary welding positioners HST CREATIVE

√ Simple controlling adapted for easy understanding by the operator.

√ Large LED display shows all necessery values of key features.

√ Internal MENU is divided into graphic blocks for intuitive orientation.

√ Digitally controlled delay of welding, rotation speed and other features.

√ Rotation speed of the spindle is controlled by the central rotary knob in standby mode for faster response.

√ Division of the values settings for rotation, for controlling the welding source, welding arm, or forming gases.

√ Program controlled and adjustable welding arm and forming gas control.

√ Possibility to save own programs and settings into a memory of the control system using a programmable interface inside of the system.

Technological functions of rotary positioners control system

Controls:

-

2 Step. This function requires the operator to press and constantly hold the foot switch or the button of the hand controller. Working cycle is started and when the foot switch or button of hand controller is released working cycle will stops. This is so-called two-motion mode. It can be active only if the Automatic rotation is not activated. Typical usage of this mode is welding when the operator sits so it is possible to immediately respond to the needs of welding rotation.

-

4 Step. This function requires the operator to press and release the foot switch or the button of the hand controller. Working cycle is started and when the foot switch or button of the hand controller is press and release once again working cycle will stops. This is so-called four-motion mode. It can be active only if the Automatic rotation is not activated. Typical usage of this mode is welding when the operator is standing. That allows the movement at working place of the operator. Spindle is rotated uninterrupted.

-

Automatic rotation. This is a mode of automatic rotation checking. That means, the spindle is rotating by a predetermined angle from 0 ° to 730 °. By the pressing of the foot switch or the button of the hand controller the working cycle is started which is automatically terminated after reaching the predetermined rotation angle. The angle of rotation can be set in block "Rotation" in the MENU of WORKING PROGRAM, see below.

-

Low speed limit. Specifies the minimum adjustable speed of rotation (RPM) of spindle rotation in STANDBY MODE. I.e. the minimum rotation speed of the spindle from which the speed can be increased. Below this value set in this block the spindle can not be rotated. Therefore, if you want to use a full speed range of positioner, it have to be adjust to 0.001 rpm. Maximum adjustable value is always equal to the maximum possible speed of specific positioner, please see the production label.

Rotation:

-

Diameter. Adjusting of welding diameter. Control system R3 will automatically calculates the progressive welding speed - the relative feed rate of the torch. This value will be displayed in the STANDBY MODE on display screen. Settings in centimeters in the range from 0.0 to 300.0.

-

Rotation direction. Settings of direction in the rotation axis (Choice: Clockwise, or counterclockwise).

-

Rotat. delay. The function can be usefull for a better material melting before welding. Adjust the delay between switching ON of the welding source and starting of the spindle rotation. Settings in seconds with an accuracy to one-tenth in the range of 0.0 to 15.0 sec.

-

Angle of rotation. Choose the total angle by which the spindle will turns around its axis. The limit is 730 °. This function is active only when Automatic rotation mode is activated in block "Controls", see above.

-

End welding angle. It defines the point where the control system R3 switches OFF the welding source. Settings in angle degrees. Limit value is 730 ° but the total value can not be higher than the value adjust in the Angle of rotation. This function is active only when Automatic rotation mode is activated in block "Controls", see above.

-

Return to 0. It defines the returning of the spindle to initial position to find the starting position of welding =(e.g., directionally defined tools), or to unwrap the energy and gas hoses. This function is active only when Automatic rotation mode is activated in block "Controls", see above.

Gas:

-

Function is active only when the positioner is equipped by the valve for the switching of the gas (optional element).

-

Pre-gas. Serves to fill up the space of weldment root by protected – forming gas. It defines how long the gas valve will be switch ON before the system gives a command to ignition of the welding source. Settings in seconds in the range from 0.0 to 15.0 s. If 0.0 s is adjusted the function is inactive.

-

Pos-gas. It defines a time how long the valve will be switched ON after the command to switch OFF the welding source has come. Settings in seconds in the range from 0.0 to 15.0 s. If 0.0 s is adjusted the function is inactive.

Torch:

-

Function is active only when the positioner is equipped with a pneumatic arm for full welding automation (optional element).

-

Before welding. Choose the type of the movement of the torch to the welded product before welding process. (Choice: Automatically, i.e. torch will be incline automatically to the product when the working cycle is starts, or Manually, i.e. the torch waits for a command via the key on the control panel, before starting of the working cycle)

-

After welding. Choose the type of the movement of the torch from the welded product after welding process. (Choice: Automatically, i.e. the torch will be moved automatically from the product after the ending of the working cycle, or Manually, i.e. the torch waits for a command via the key on the control panel, after the ending ofthe working cycle)

Welded parts:

-

It can go about any part that fulfils the dimensional and weight restrictions of positioner without limitation of welding methods.

-

The welding process can take place at any angle of inclination of the spindle within the capabilities of positioner. This is completely unindependent on the eccentric load of the positioner by means of digital drive concept.

-

The control system is able to control the angle of rotation and the angle of switching the welding source off unindependently to each other. There is a possibility to reach the perfect connection of weld bead by the automated welding. Of course, there is a possibility of manual controlling.

|

WORKING PARAMETERS |

VALUE |

|

Maximal static loading |

2000,0 Kg |

|

Torque on the main spindle shaft |

5460,4 Nm |

|

Speed range |

0 - 1,7 rmp |

|

Working loading ** |

24/7 |

| TECHNICAL PARAMETERS |

VALUE |

| Diameter of the spindle flange - recommended diameter of universal chuck | 315,0 mm |

| Recommended working plate | 1350,0 x 21,0 mm |

| MOTION AXES | VALUE |

| Rotation of spindle | Controlled axis |

| Length of stroke | 630 mm, axis controlled by buttons |

| TECHNOLOGY OF WELDING AND CONTROLLING | VALUE |

| Suitable methods of welding | MIG/MAG TIG, Plasma Weld, Laser |

| Electric current for DC transfered by spindle | 450A |

| Electric current for AC transfered by spindle | 550A |

| Connection of the welding source through START/STOP system | Yes |

| Foot switch for the main spindle rotation regulation and START/STOP function * | Yes |

| ELECTRIC POWER AND CONNECTING PARAMETERS | VALUE |

| Electric power supply | 3x400V/N/PE/50Hz |

| Compressed air (dry, clean) * | 0,5 - 0,7 MPa |

| Protective gases for the root protection * | 1 independant way |

| Description of the working place | Stand design, recommended to anchor |

| Level of IP | IP 51 C |

| Input power *** | - |

| DIMENSIONS | VALUE |

| Height | 2152 mm |

| Width | 1994 mm |

| Depth | 1355 mm |

| Net weight (without clamping element) *** | 700 Kg |

* Optional item, or more versions are available which differs according to function. Mentioned parameters are valid for maximal options.

** 8/5 = lower loading in one duty period /// 16/6 = industrial loading /// 24/7 = non - stop loading

*** Parameters can not be provided with 100% correctness. Configuration of the machine must be taken into consideration. Mentioned parameters are valid for reaching maximal effective value.

...Subject to change the technical parameters without notice.