Assembling Line ASSEMBLER

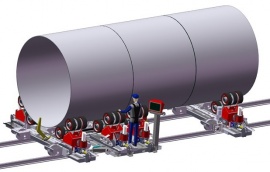

Machine is suitable for assembling and welding of tanks of high dimensions and for parts of tanks (also for pillars, supports, etc.) of high weight. Operation program with paralleling of part is understandable, which means that assembling of parts and its preparation is simple. Assembling line is suitable for integration into production lines of heavy industry for assembling of products because of welding possibility.

This is a special solution which is provided only as custom made. Due to the complexity of the whole system and its parts very thorough consultation of requirements is always necessary. The final technical solution and possible feasibility of the project is provided as special project solution and always exactly based to the parameters of the required products, specific applications or the customer production program.

-

ASSEMBLER CONTROL WELDING is by computer controlled assembling line suitable for assembling and welding of high capacity tanks surfaces and of different kinds of tubular beams with maximal turning diameter up to 5000mm and maximal loading of 25 000 Kgs.

-

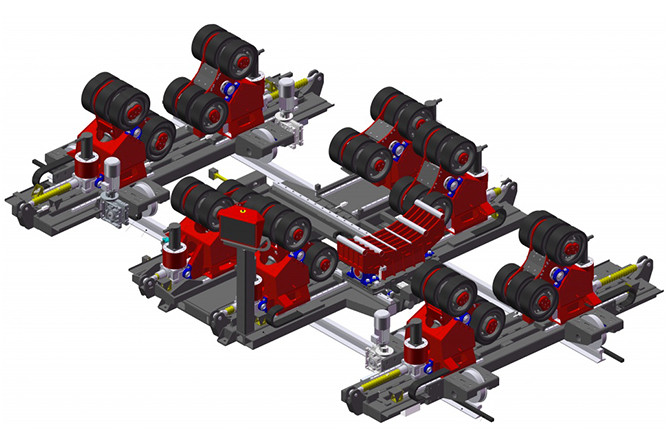

Mechanical construction of the device consists of three independent parts to which are in total four pairs of roller units added. The unit works as completelly controlled unit and its parts are depended to each other.

-

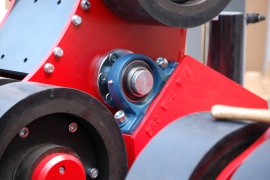

First part of the device is the body of the machine placed on steel wheels and freely moveable along the rails. To this part the first pair of roller unit is added and these units are equipped with twelve rollers of surface from vulcanized rubber. Wheelbase of the rollers is controlled by computer and realized through the system of high – efficient step motors which are connected to gearbox through electric safety brake

-

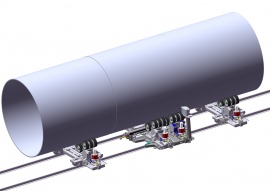

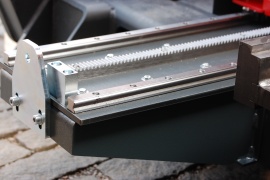

The second part is fixed on the rails and on the platform the second and the third pair of roller position ballscrews are connected. In the middle of this part is self – adjustable base for pushing the tank away placed on two massive linear bearings. By adding another part of the tank, the base is driven by motor and is designed as controlled axis. The second pair of roller units is placed on precise moveable (100mm) longitudinal bearings and driven by hydraulic cylinders which are there for assembling of another part – DRIFT. This part is equipped with eleven rollers of surface from vulcanized rubber and with one roller of surface from CrNi steel which are driven by synchronized high – efficient digital controlled motors – all of the rollers are driven. The third pair of roller unit is equipped with eleven rollers of surface from vulcanized rubber and with one roller of surface from CrNi steel. Wheelbase of the second and third pair of rollers controlled by computer is realized through the system of high – efficient step motors connected to to gearbox with ballscrew through electric safety brake. Into the second part fluxing pad is integrated with the system of flux feeding for inner weld.

-

The third part is placed on steel wheels and is motoric - longitudinally moveable along the rails during assembling of another part of the tank of the same lenght of the movement as the welded tank. This part is equipped with the fourth pair of roller units which are equipped with twelve rollers of surface from vulcanized rubber and driven by high – effective digital controlled motors – all of the rollers are driven. Wheelbase of the second and third pair of rollers controlled by computer is realized through the system of high – efficient step motors connected to to gearbox with ballscrew through electric safety brake. The fluxing pad is vertically moveable with possibility of adjusting the pressure which influences lower part of welded tank. The flux is feeded under the weld and flux that is not used is brought back to the feeder.

-

Stand of operator is placed between the second and the third pair of roller units. Display with touchscreen is placed on operator‘s right side and the whole system can be controlled by this display. It goes about sophisticated composition of automatic and half – automatic functions designed as independent cycles of working operations. For tacking of two assembled parts TIG method of welding is used, performing of inner and outer welds is realized through the system of tower automat suitable for any mothod of welding. ASSEMBLER can be connected to working station of two towers through the system of digital remote control designed for process of welding. Control system and all electronics are placed in two distribution boxes.

Main benefits

√ High incresement of productivity caused by elimination of delay time spent by manipulation and also incresement of welding quality because of precisely assembled parts.

√ Possibility of welding inner and outer welds directly after the process of tacking without needs to manipulate with the tank, root is protected by fluxing pad.

√ Sequential system of assembling and movement of the tank along the rails on the third part does not require to use the crane.

√ Sophisticated system of sequential production of FIFO philosophy combined with fully manual controlling can cover all of the needs.

√ High safety standards because of clamping of assembled parts in roller units, safety brake system and falling sensors.