Beveling Automat ACU Cutter

This system is designed for producers of pressure tanks as an production alternative of ordinary chipping tooling of welded surfaces. In the connection with plasma of HQC type and filtration unit with air recovery CUTTER means high – tech technological unit with unique performance.

This is a special solution which is provided only as custom made. Due to the complexity of the whole system and its parts very thorough consultation of requirements is always necessary. The final technical solution and possible feasibility of the project is provided as special project solution and always exactly based to the parameters of the required products, specific applications or the customer production program.

-

CUTTER TOWER is automat suitable for production of welded surfaces and centric holes of bases of pressure tanks with maximal turning diameter up to 5000 mm and with weight which is determinated according to maximal thickness of the base wall of 30mm.

-

To principal welded body of the machine reinforced in 90° turning and pneumatically driven arm is connected on which precisely mounted centre unit of londitudinal and vertical movement with torch head is placed. The body is connected to unit of main spindle through the system of spinal frame with torse reinforcement. The spindle carriers three armed system determinated for base fixation.

-

The central unit of londitudinal and vertical movement of torch head in X and Z axises is placed on precise linear bearings with ball bearings. Servomotor is connected to planetary gearbox and both axises are driven by it. In mechanism of X axis precise copy system, based on pneumatical princip, is integrated. Z axis is consisted of vertical beam welded from precise alluminium parts and is ended by the joint of the torch head. Torch head is tilted in T axis with elevation in the range of – 40 - + 55° and is driven by step motor which is connected through planetary gearbox and by which toothed belt is used. Through the hollow shaft, which creates the joint of placing the head as well, cables and hoses for gas and energy distribution into plasma torch are brought. The torch is supported by the holder made out of duralumin on which the device for precise adjustment of distance between the torch and surface of the base is placed.

-

Principal spindle of rotation is made up of hollow shaft placed in bearing. The spindle is driven by high – efficient step motor through the system of planetary gearbox and toothed belt. On the spindle three armed construction for support of bases is mounted and this constrcution is equipped with longitudinally moveable and self – supporting holders with integrated vacuum support for clamping the base. Lateral parts of three armed construction are equipped with linear bearings on which measuring tools for precise centering of the base are placed.

-

Machine can be delivered with exhaust system of two ways integrated into centre exhaust unit through separator of sparks. One of the ways of exhausting is realized through the hollow shaft of main spindle and brought directly under the place where the proces of beveling of bases is realized. The second way is realized through especially constructed external tower mechanically controlled by rack gearbox. The tower carriers steel tube ended by resistant exhaust nozzle. The whole system is connected to separator of sparks through flexible and heat – resistant hose. Changing of exhaust ways is automatically controlled by control system as well as swiching the exhaust system on/off.

-

Control panel is located in transmission box which is connected through the cabel with control system (located in principal tower of the machine). Programming of the machine is designed as visual with possibility of putting the key data and adjustment. From these programs compilations of programs can be done. These compilations enable to realize difficult cuts with bezel or cuts of X type automatically. Key technology which eliminates inaccuracies of production is electrically realized measuring of base surface when the machine starts (before the whole operation is started) with measuring of current value of the base and on the basis of this information finds the program, which means that finished base has the total dimensional inaccuracy of 1,0mm without taking its initial shape inaccuracies from production into consideration. X, Z, T axises are interpolated by control system, finding of positions is fluent and taking spatial possibilities of the base (including positioning) into consideration.

-

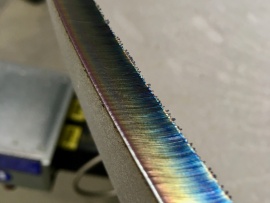

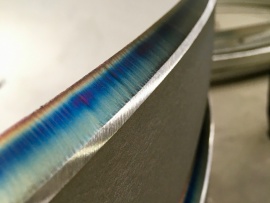

As the source of plasma, high – quality plasma generators from reputable producers are used and chosen according to production targets of the customer. Also oxygen plasma can be used for alloy steel. However, more favorable is to use plasma of HQC type. On the basis of detailed testing this method is certificated and enables to perform the welding immediately without neccessity of cutting surfaces sharpening even for TIG and MAG methods.

Main benefits

√ Large incresement of productivity in comparism of chipping methods of welded surfaces tooling.

√ Preparation of multiple inner and outer bevels, bezels, X lines or possibility of production of centric holes with/without beveling.

√ Torch head with the range of elevation -40 - +55° with copy system of surface by pneumatical system.

√ Adaptive electrical measuring of base surface, accuracy of torch positioning of 0,2mm, high and stable accuracy of tolerance up to 1,0mm.

√ Placing of arm with torch away from base support enables easy manipulation with crane or forklift without limits.

√ Sophisticated system of exhausting eliminates about 99% of emissions not only during the proces of beveling of base but also during holes cutting.

|

WORKING PARAMETERS |

VALUE |

|

Maximal static loading |

5900,0 Kgs |

|

Torque on shaft of main spindle |

5350,5 Nm |

|

Static angle clearance of main spindle |

< 55,0 arcmin |

|

Speed range of main spindle |

0,01 - 2,08 rpm |

|

Duty cycle ** |

24/7 |

| DIMENSIONS |

VALUE |

| Optimization for arched bases according to standards | - |

| Minimal diameter of cut base | 800,0 mm |

| Maximal diameter of cut base | up to 5000,0 mm |

| Maximal height - depth of cut base | 1390,0 mm |

| Minimal diameter of the hole (rotation of base in axis) | 60,0 mm |

| Maximal diameter of the hole (rotation of base in axis) | 690,0 mm |

| Minimal thickness of cut base | 2,0 mm |

| Maximal thickness of cut base | 50,0 mm |

| MOTORIC AXISES | VALUE |

| Rotation of main spindle | Controlled axis |

| Rotation of arm with central holder of torch head into PARK position (R axis) | 90°, special axis |

| Longitudinal movement of central holder of torch head (X axis) | Full range, controlled by program |

| Stroke of torch head (Z axis) | 1220,0mm, controlled by program |

| Elevation of the torch by circumferential cut (T axis) | + 55 až -40 °, controlled by program |

| Elevation of torch by cut of inner hole (T axis) | +/- 45 °, controlled by program |

| Copy system (pneumatic adjustment of pressure power) | +/- 50,0mm, special axis |

| Adjustment of position of clamping segments | Full range, 3x manual axis |

| Adjustment of position of cut base by special tool (height) * | 930,0mm, manual axis |

| Adjustment of position of cut base by special tool (centring) * | 105,0mm, manual axis |

| TECHNOLOGY OF WELDING AND CONTROLLING | VALUE |

| Suitable methods of cutting (types of generators) * | Focus Plasma, HQC Plasma |

| DC current for plasma generator transfered through the spindle | 250A |

| Fixative system of cut base | 3x vacuum |

| Gas console integrated in the tower | Yes |

| Remote control | Yes |

| POWER SUPPLY | VALUE |

| Power supply | 3x400V 50/60 Hz |

| Pressure air (dry, clean) | 0,65 - 0,9MPa |

| Integrated exhaust system of fumes | 2 automatic ways |

| Design | Recommended to fix |

| Level of IP | IP 51 C |

| Input for installation *** | - |

| DIMENSIONS | VALUE |

| Height *** | - |

| Width *** | - |

| Depth *** | - |

| Net weight *** | - |

* Optional item, or more versions are available which differs according to function. Mentioned parameters are valid for maximal options.

** 8/5 = lower loading in one duty period /// 16/6 = industrial loading /// 24/7 = non - stop loading

*** Parameters can not be provided with 100% correctness. Configuration of the machine must be taken into consideration. Mentioned parameters are valid for reaching maximal effective value.

...Subject to change the technical parameters without notice.